- About Allevi

- Bioprinters

- BioinksAdditivesAdditivesBioinksAdditivesAdditivesAdditivesAdditivesAdditivesAdditives

- Software

- Services

- Resources

- Support

Menu

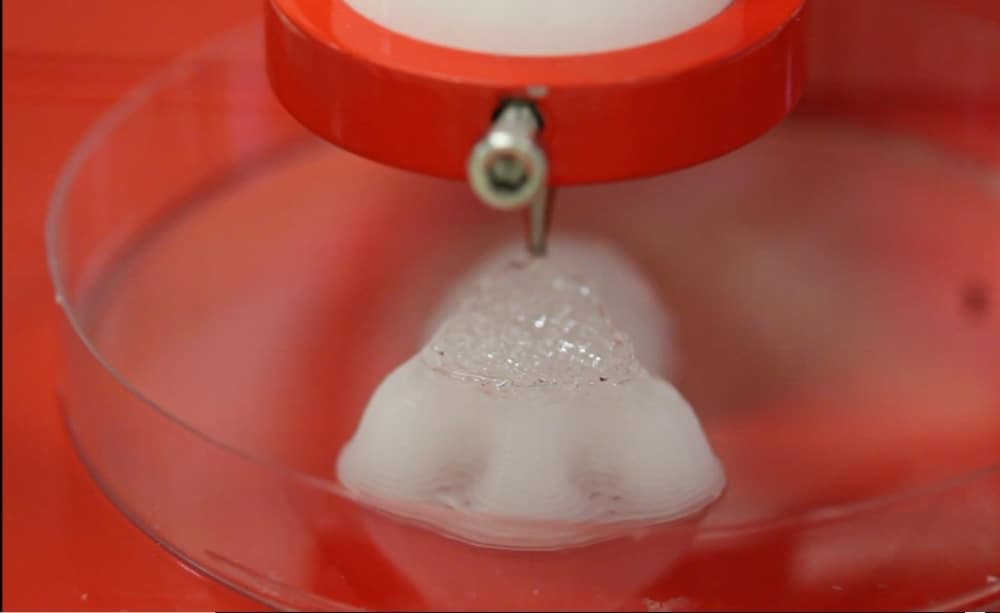

Polycaprolactone (PCL) is a popular bioprinting material because it offers the advantages of a hard plastic while remaining biocompatible and biodegradable. Although it is commonly used, bioprinting PCL can be tricky at first. Follow these troubleshooting tips for bioprinting PCL to help overcome common issues and improve your final PCL bioprints!

We hope that you found these tips for bioprinting PCL helpful! If you’re still troubleshooting after this guide, your PCL printing might also benefit from following the Print Parameter Optimization Guide. Additionally, you can email the Allevi Customer Success Team at [email protected].