Through regular use, the rack and pinion connection between your Allevi 2’s extruders can become misaligned. This can result in clicking noises, extruders jumping, and inaccurate Z-coordinates. You can follow this extruder alignment guide to realign your Allevi 2 extruders and get back to work!

Extruder Alignment Instructions

Physical Re-Alignment

- Turn your Allevi 2 off using the power button on the front of the frame.

- Ensure that the extruders are moving freely by gently nudging the right extruder up and down by hand.

- Gently move the left extruder to its uppermost position.

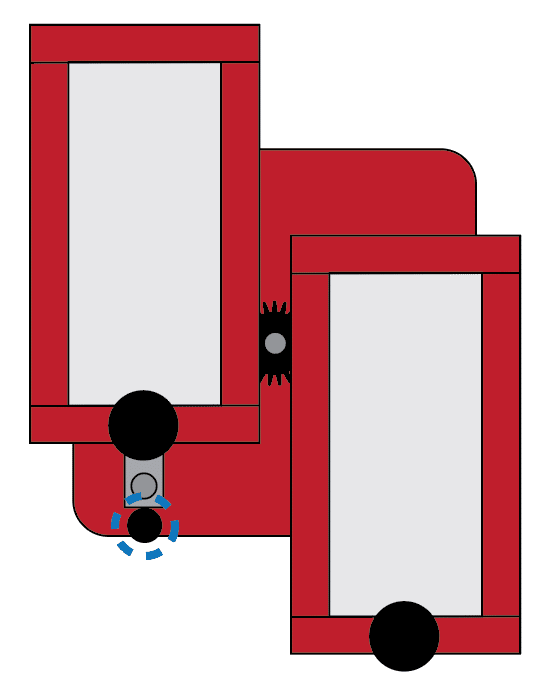

- Remove the lower left bumper (see the blue dotted circle in the figure below) by unscrewing it with a counterclockwise motion. The small rubber piece should be fully removed and kept somewhere safe for later use.

- The rubber bumper may be tight at first. Feel free to use blunt pliers to initially loosen the piece.

- Gently slide the right extruder up until it hits the upper right bumper. Keep a hand on the left extruder as it moves down.

- When the right extruder reaches the top of its track, put a small amount of upward pressure on it. Simultaneously, gently slide the left extruder down. This will remove the left extruder.

- With the left extruder in hand, continue applying slight upward pressure on the right extruder to keep it at the top of its track.

- Begin sliding the left extruder back onto the left track. When you feel the left extruder re-engage with the gear in the middle of the carriage, begin gently lowering the right extruder as well.

- If you have the gear and extruders aligned properly, the extruders should slide past each other smoothly, without making any clicking noise on the gear.

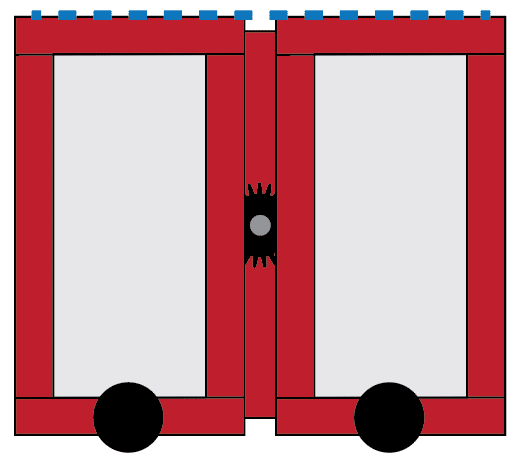

- The extruders should also be level in the middle position (see the blue dotted line in the figure below).

- When you have both extruders on their respective tracks, and they appear to be roughly level, gently raise the left extruder.

- Replace the rubber stopper under the left extruder.

Testing With User Interface

- Turn the printer back on.

- Watch the boot-up process to see if the extruder homing completes smoothly.

- If homing results in any jumping or clicking, repeat the previous steps from the beginning.

- If you have already repeated the above steps and are still having issues, contact the Allevi Support Team: [email protected].

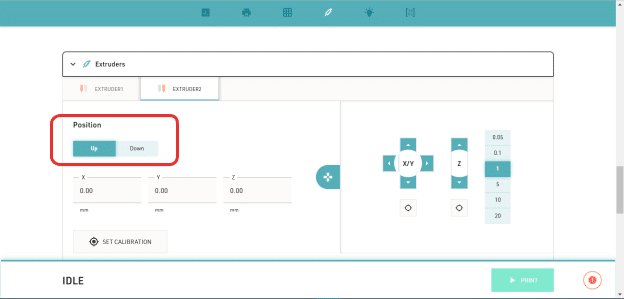

- After boot-up, open the Bioprint Online Dashboard and navigate to the ‘Up’ and ‘Down’ buttons in the position settings of the “Extruder” section (see the red rectangle in the figure below).

- With Extruder 1 selected, use the ‘Down’ button to lower the left extruder into the printing position. Then, use the ‘Up’ button to return the left extruder to the middle position.

- If no jumping or clicking occurred, repeat the previous step with Extruder 2 selected.

- If no jumping or clicking occurred, go to the “Advanced” section of the dashboard.

- Open the gcode console and enter

G28 E0to rehome the extruders. - If no jumping or clicking occurred, then the extruders should be properly aligned. Nice work!

- If jumping or clicking does occur during the software testing of either extruder, repeat the protocol from the first step.

You can also follow along our extruder alignment video below:

If after repeating the protocol you are still having issues with extruder alignment, contact the Allevi Support Team by emailing [email protected].

Ready to bioprint? Check out our protocols page to find helpful bioprinting guides.