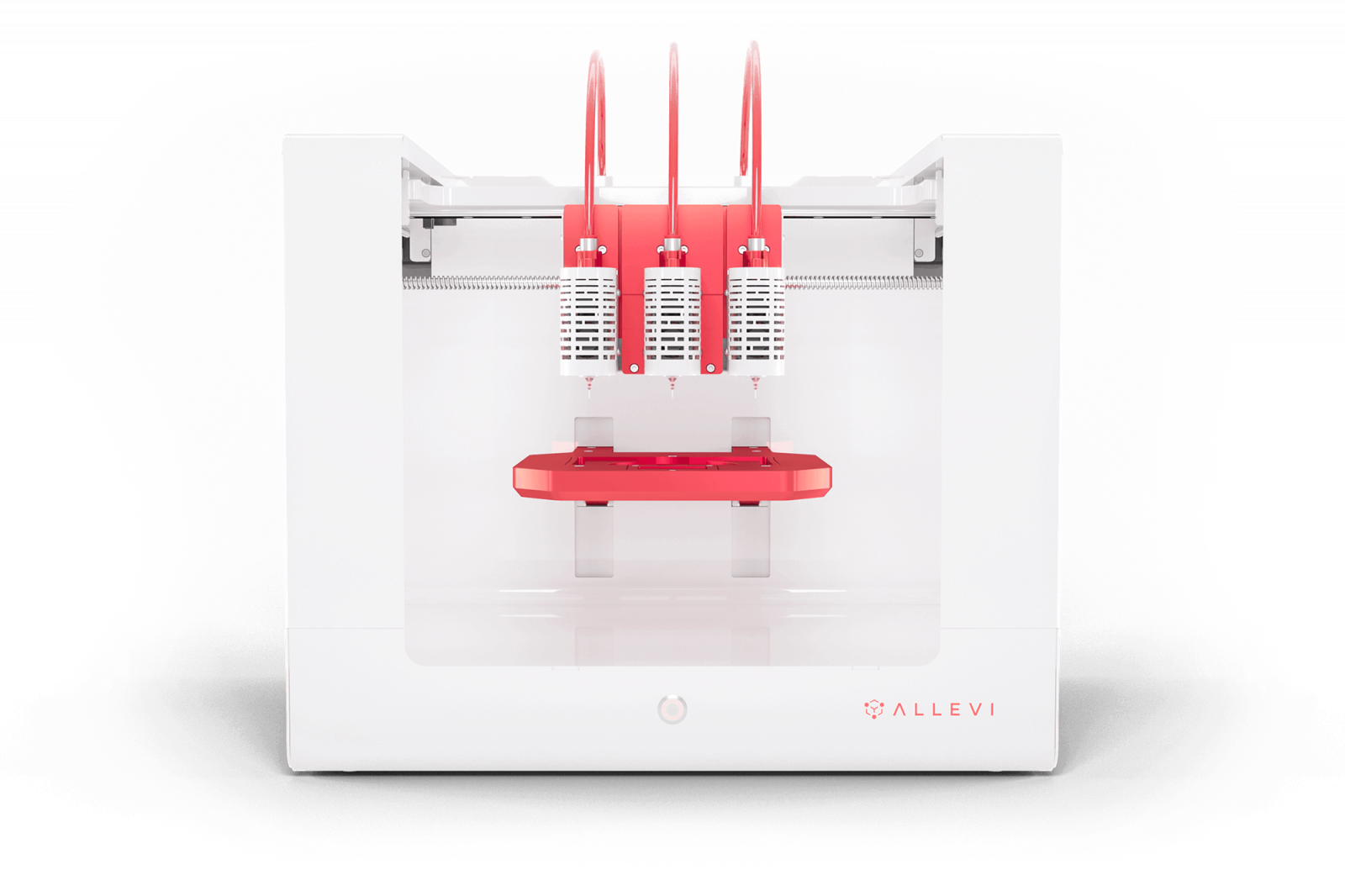

Allevi 3

The Bioprinter for Every Research Application Soft Tissues Microfluidics Disease Modeling Vasculature Organ-on-a-Chip

Bring your Work to Life

The Allevi 3 bioprinter empowers you to print any cell line, into a variety of geometries for a broad range of applications. Allevi 3 will exceed your needs today and has the versatility to grow with your work.

Designed and optimized for research in:

- Tissue engineering

- Materials science

- Regenerative medicine

- Disease modeling

- 3D culture

- Organ-on-a-chip

- Microphysiological systems

- Drug delivery

Important update regarding our Allevi product offerings at 3D Systems.

After careful consideration and evaluation, we have made the strategic decision to discontinue production of the Allevi 3 Bioprinter, effective July 27, 2023.

TECHNICAL SPECIFICATIONS

-

Extruders 3 × Allevi CORE Extruder

-

Photocuring LED – 365nm and 405nm

-

Printing Technology Fused Deposition Manufacturing (FDM)

-

Compatible Syringes 5 mL plastic, 5 mL metal

-

Min. Temp 4˚ C

-

Max. Temp 160˚ C

-

Min. Pressure 1 PSI

-

Max. Pressure 120 PSI

-

Pressure Variance ±0.1 PSI

-

Heated Bed Temperature Ambient – 60˚ C

-

Construction Aluminum Frame

-

X, Y Precision 1 μm

-

Z Precision 1 μm

-

Build Volume (W × H × D) 3.5 × 2.4 × 5.1 in (42.8 in³)

-

Build Volume Metric (W × H × D) 9 × 6 × 13 cm (702 cm³)

-

Supported Build Plates Slide, Petri Dish, Well Plate

-

Dimensions (W × H × D) 18.4 × 15.2 × 14.2 in

-

Dimensions Metric (W × H × D) 46.7 × 38.8 × 36.0 cm

-

Weight 40 lbs (18.1 kg)

-

Power Requirements AC 110V – 220V