Allevi Blog

Allevi Authors Develop a Novel Cellulose-based Bioink

- Updated on April 24, 2020

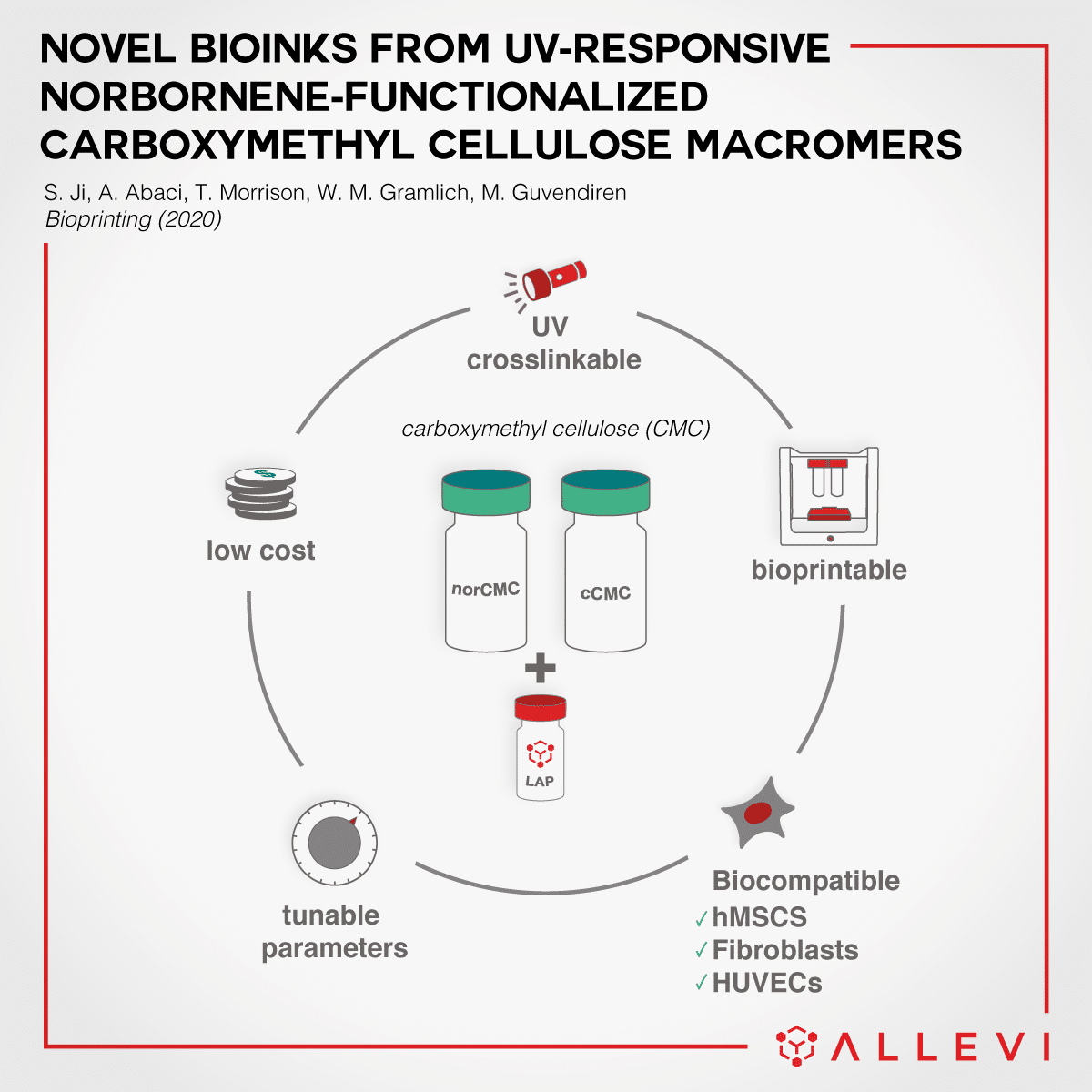

A bioprinted construct is only as good as the bioink used to create it. There are many biomaterial options available on the market, however, the need for more customized hydrogels is growing. This demand is driven by new applications and printing techniques and cells used in bioprinted models. Shen Ji, together with colleagues, added a new bioink to the biomanufacturing arsenal to meet this demand. Their research was recently published in the Bioprinting journal and titled “Novel bioinks from UV-responsive norbornene-functionalized carboxymethyl cellulose macromers”.

A New Formula for a Cellulose Bioink

To create this novel bioink, researchers from New Jersey Institute of Technology and the University of Maine based their work on carboxymethyl cellulose (CMC). CMC is a water-soluble chemical derivative of cellulose which is a highly abundant natural polymer with great biodegradability and biocompatibility. Cellulose is a popular choice as a bioink because of its low cost and biocompatible properties, however, it’s not always easy to bioprint. Usually, cellulose has to be mixed with other materials (i.e. alginate) to enable photocrosslinking in order to make the bioink curable.

The novel bioink presented in the study is however fully photocurable without a need to add any other components. This was achieved by functionalizing CMC with either an amide or an ester linker to obtain norbornene CMC (NorCMC) or carbic CMC (cCMC). When combined with LAP, a photocrosslinking bioink, this new biomaterial can rapidly turn into a hydrogel when exposed to visible blue light.

By controlling the bioink concentration or ratio of chemical modifiers, mechanical properties of NorCMC and cCMC can be fine-tuned; making them versatile hydrogels that can be adjusted to specific experimental conditions. The right formulation of the bioink allowed for precise extrusion using low pressure and high printing speeds on the Allevi 2 bioprinter.

Fully Biocompatible

Once the team showed the ability to quickly and easily bioprint this novel material – they then looked at its compatibility with living cells. In this case, NorCMC and cCMC displayed excellent support for fibroblasts, human mesenchymal stem cells, and human umbilical vein endothelial cells. All these cell types have a wide range of research applications: from tissue modeling, to vasculature bioprinting, to regenerative medicine. Furthermore, the ability to functionalize NorCMC and cCMC using cell attachment peptides makes it possible to adjust the material for other, more demanding cell types.

As cellulose is a widely abundant natural polymer, these novel bioinks are very cost-effective, which may be especially useful for big-scale bioprinting and high-throughput applications. This also lowers the barrier of entry for laboratories that would like to start bioprinting using biologically relevant materials without spending a large portion of their lab budget. We can’t wait to see how this will be applied in the future!