Allevi Blog

Novel composite cellulose-based bioink from Allevi Author

- Updated on April 29, 2020

Bioprinting always requires consideration of many different parameters: biomaterial mechanical and biological properties, printability, cell viability and many more. It requires finding a fine balance between all the factors and the golden mean is not always easy to achieve. Allevi Authors from the University of Adelaide in Australia decided not to compromise any aspect of bioprinting and created a composite bioink that scores the top marks in all the departments.

Not another One-Trick Pony

There are many biomaterials that are great in just one thing but fail in others. For example, some can sustain a lot of mechanical stress, however, they are not compatible with cells. Or the other way around. But by combining the best hydrogels in their category it is sometimes possible to obtain a real swiss-army knife of a hydrogel. Hadi Rastin and co-authors of a publication titled “3D Bioprinting of Methylcellulose/Gelatin-Methacryloyl (MC/GelMA) Bioink with High Shape Integrity” achieved just that by combining methylcellulose (MC) and gelatin-methacryloyl (GelMA).

The new GelMA/Methylcellulose bioink

These hydrogels alone show great but different properties. MC is well known for its printability, but unfortunately, it dissociates in cell culture relatively quickly, rendering it unsuitable for longer culture periods. GelMA, on the other hand, with its photocrosslinking mechanism creates stable hydrogels, but print resolution may suffer from problems with shear-thinning of the material.

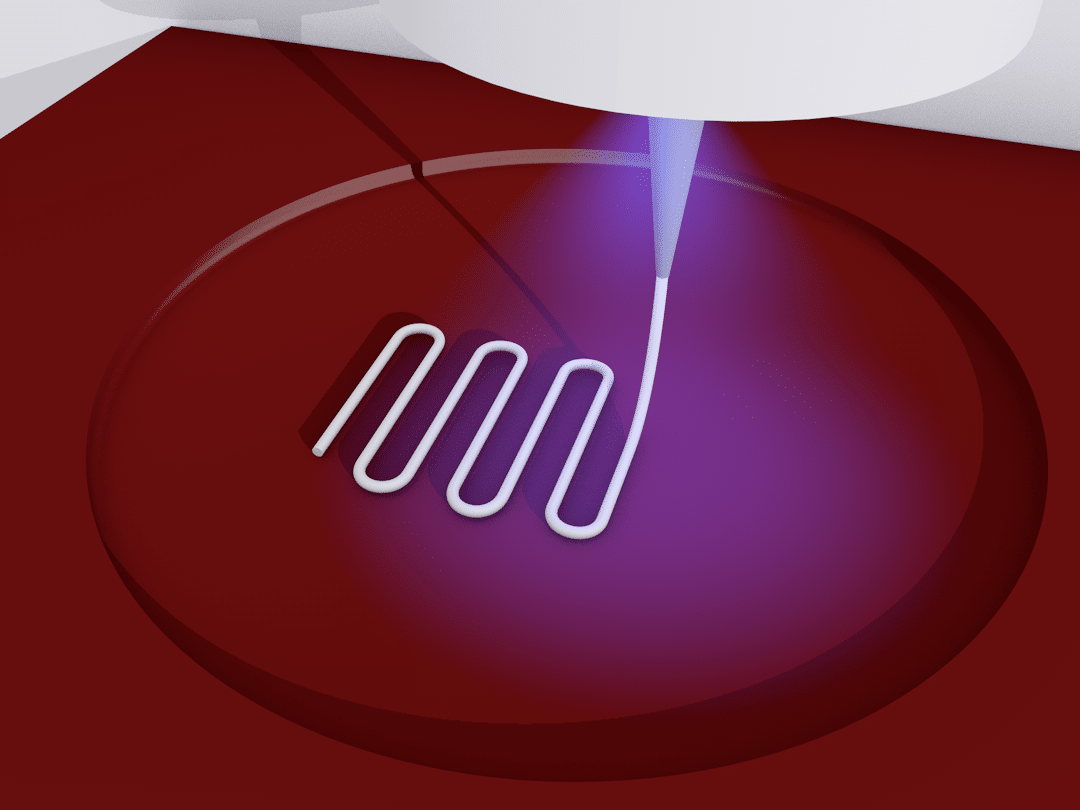

In a recent publication in Applied Bio Materials, Allevi Authors introduced a new bioink composed of MC and GelMA mixed together. The resulting hydrogel shows great printability properties. Its improved yield stress allows for the self-support of the construct during printing that can be later cross-linked using blue or UV light. It means better construct stability and shape fidelity comparing to GelMA or MC alone. After placing a construct in cell culture media it can remain undisrupted for several months significantly improving dissociation problems of the pure MC making it a great candidate for tissue engineering, allowing for slow replacement of the scaffold with a host ECM. GelMA well known for its biocompatibility didn’t loose cell support properties upon combining it with MC. Researchers showed the high viability of human osteoblasts encapsulated in the novel composite bioink and bioprinted using Allevi 2.

This research shows again that by combining two materials with well-known characteristics it is possible to obtain a superior hydrogel that combines favorable properties of the two.