Case study: Bioprinting Hydroxyapatite and PCL — Hydroxyapatite and polycaprolactone blends have been previously investigated as scaffolds for bone tissue engineering [1]. In addition to its biocompatibility, hydroxyapatite offers osteoconductive properties. However, with a high melting temperature and insolubility in water, hydroxyapatite presents challenges for extrusion bioprinting. When mixed with polycaprolactone, which exhibits a low melting point, the blended materials can be printed together [1]. Below are sample print parameters for a hydroxyapatite and polycaprolactone blend with the Allevi 1.

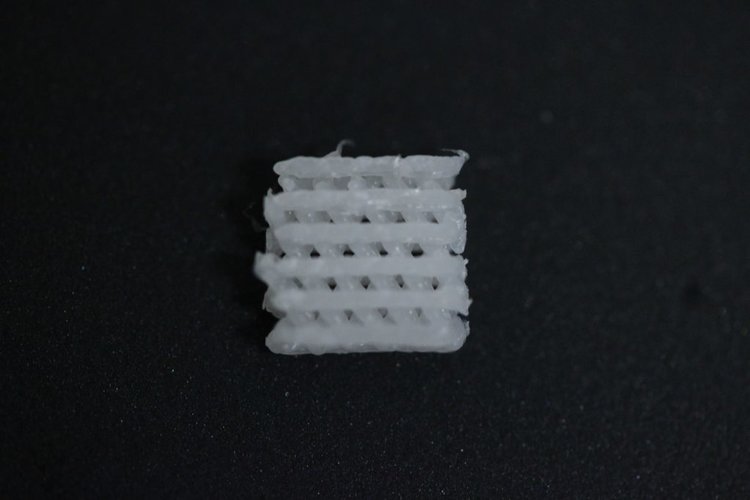

First, polycaprolactone (PCL) was melted on a glass plate at 100°C. Very carefully, 20% (w/v) hydroxyapatite was mixed into the PCL. Then, this mixture was loaded into an Allevi metal 10 ml BD syringe. A metal 27 gauge needle was placed onto the tip of the syringe and loaded into the first extruder of the Allevi 1. The extruder was then heated to 120°C. A lattice, imaged below, was completed at a pressure of 100 PSI with an approximate resolution of 0.3 – 0.4 mm.

| Speed (mm/s) | Layer Height (mm) | Nozzle Diam (mm) | Gauge | Pressure (PSI) | Print Temp (°C) |

|---|---|---|---|---|---|

| 0.5 | 0.2 | 0.3 | 27 Tapered | 100 | 120 |

We hope this case study helps you determine if bioprinting with hydroxyapatite and PCL is right for your application. Another common bone printing method is with Hyperelastic Bone.

References

- Park, Su A. Fabrication of porous polycaprolactone/hydroxyapatite (PCL/HA) blend scaffolds using a 3D plotting system for bone tissue engineering. Bioprocess Biosyst Eng. 2011 (34). pp. 505-513.