Overview

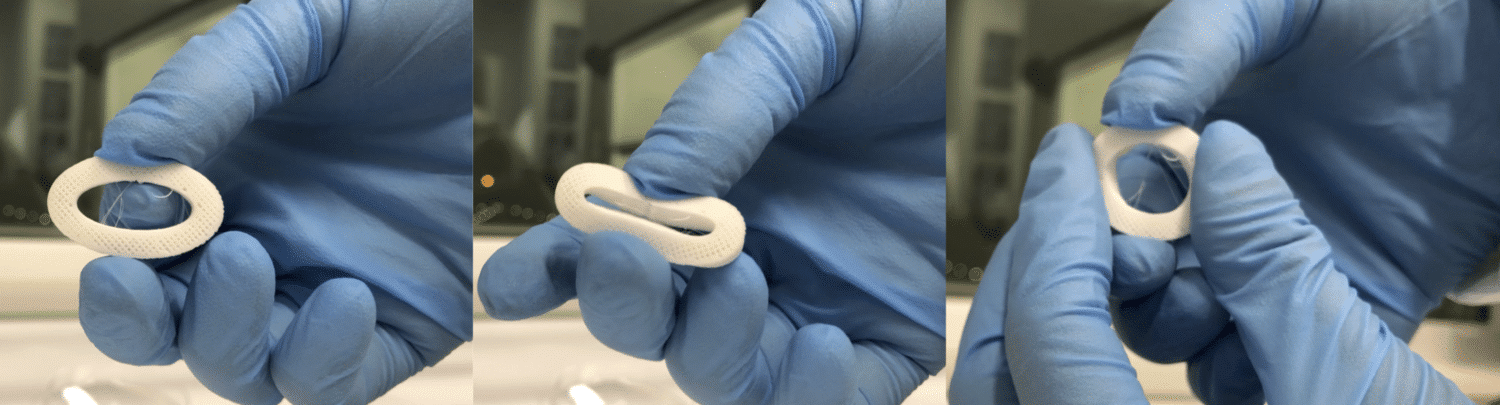

Hyperelastic Bone™ is a material made by Dimension Inx composed of over 90% hydroxyapatite, a naturally occurring mineral from bone tissue. Hyperelastic Bone™ is printed at room temperature and can be seeded with cells post-print. Use this step-by-step protocol for bioprinting bone tissue using Hyperelastic Bone.

The recommended preparation provided in the user instruction below yields a streamlined printable biomaterial that creates reproducible 3D bioprinted constructs. However, preparation can be modified by users to suit their needs.

Materials

- 3 mL Dimension Inx Hyperelastic Bone™ (Note: this product is no longer commercially available)

- Bioink mixer

- Allevi 5 mL syringe

- 14G metal drawing needle

- 27G metal printing needle

- Allevi sandpaper printing surface

- Mesenchymal stem cells

- Mesenchymal stem cell growth medium

Methods for Bioprinting Bone Tissue

Printing:

- Remove your vial from 4˚C and let it reach room temperature;

- The material will look hardened right as it is taken out of the fridge, so wait for it to look fluid before handling it (this may take more than an hour and varies according to room temperature);

- Vigorously vortex the material using the bioink mixer until it is uniform (this may take several minutes);

- NOTE: If it seems that the material solvent is mostly separated from the powder, you may secure your vial to a vortex mixer with tape and leave it on for at least one hour. Mixing your vial for longer periods of time will allow for a better printing experience.

- Use the 14G needle to puncture the vial’s cap and draw your print session quantity (3 mL), without turning the vial upside down to prevent material loss. Hyperelastic Bone™ is highly viscous, so loading may take a few minutes. We recommend that you use this vial for only one print session. If you use it for more sessions, make sure to appropriately seal it. It is advisable to switch the punctured cap to a solid cap for better further storage;

- After drawing the material, remove the syringe plunger and drawing needle;

- Remove the stopper from the plunger and place it in the syringe;

- Place the stopper back in the syringe, pushing it with the plunger until it touches and evenly distributes the drawn material in the syringe. Make sure that, while pushing the stopper with the plunger, they do not re-attach;

- Place the 27G printing needle and load your Allevi!

- Place the adhesive printing surface on your petri dish.

Post-printing:

- Let your printed construct sit in a fume hood for at least 2 hours before handling it. Note that prints can be stored indefinitely in airtight glass containers before washing;

- Submerge your printed construct in 70% ethanol for at least 1 hour. Gentle agitation is recommended. Change the ethanol and leave your object submerged for another hour;

- Replace the ethanol with PBS (sterile PBS for biological applications), and use it immediately. If you desire to store this object, freeze it at -20 ̊C, – 40 ̊C or -80 ̊C;

- If you did not use our dish and your construct fused with your surface, carefully use a razor blade to remove it. If you did use our dish, simply remove your construct while wearing gloves;

- If you desire, you may cut your print with scissors, scalpels, biopsy punches, etc.

Cell seeding:

- Aspirate any excess liquid from your printed construct, but do not let it dry completely. It should be slightly moist for cell seeding;

- 10-15 μL should be seeded in a 5 mm diameter, 1 mm thick printed construct;

- Gels can also be injected into bioprinted and washed objects.

Print Settings

| Speed (mm/s) | Layer height (mm) | Nozzle Diam (mm) | Gauge |

| 26 | 0.2 | 0.2 | 27 |

| Pressure (psi) | Crosslink (sec) | Print Temp (°C) |

| ~30-40 | 0 | Room Temperature |

Warnings for Bioprinting Bone Tissue

- Do not store Hyperelastic Bone™ in liquid form in plastic containers for several hours, or it will dry out. Try to limit any and all air exposure before printing in order to ensure the best printing experience;

- Printing with needles of higher gauges (smaller nozzle diameters) than the ones provided may cause intermittent clogging;

- Do not let Hyperelastic Bone™ in liquid form come into prolonged contact with ferrous metals, it will corrode them.

- Do not let Hyperelastic Bone™ come into contact with polyesters or polystyrenes, it will fuse with them.

- Do not let Hyperelastic Bone™ reach temperatures above 70 ̊C, or it will melt.

- Do not try to sterilize printed constructs with heat, steam, ethylene oxide, or hydrogen peroxide. This material contains methylene chloride, 2-butoxyethanol, and dibutyl phthalate.

- For research purposes only. Not for human or clinical use.

References

Jakus et al. Hyperelastic ‘bone’: A highly versatile, growth factor-free, osteoregenerative, scalable, and surgically friendly biomaterial. Science Translational Medicine. 8(358). 2016.