Overview

LifeSupport® is the core component and industry standard for Freeform Reversible Embedding of Suspended Hydrogels (FRESH) 3D bioprinting. Each LifeSupport printing kit comes with five 2 g units of sterile, dried, LifeSupport powder which is composed of gelatin microparticles of defined size and shape. Each unit rehydrates to approximately 20 mL of LifeSupport material. Follow this protocol for FRESH bioprinting using LifeSupport.

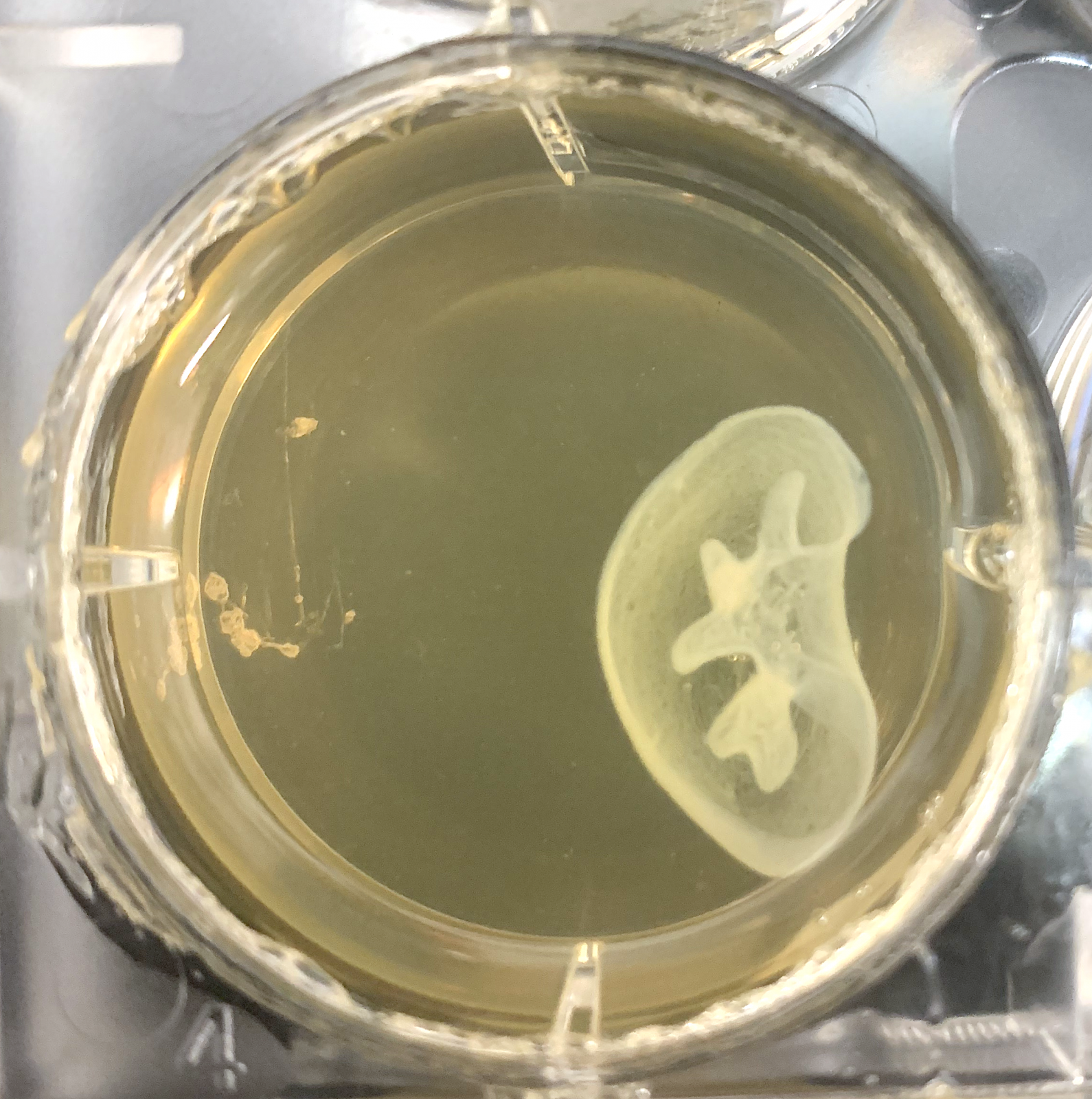

FRESH 3D bioprinting is performed by extruding bioinks and other materials within the hydrated, compacted LifeSupport® support material, which is specially formulated to prevent constructs from collapsing and deforming while printing. A wide range of polymer crosslinking chemistries and gelation mechanisms are supported within LifeSupport® by the incorporation of ions, enzymes, pH buffers and more into the support material during the rehydration process.

LifeSupport® allows for FRESH 3D bioprinting of soft hydrogel bioinks in complex geometries without the need for sacrificial support inks (e.g., Pluronic® F-127, polycaprolactone, gelatin) or ink modifiers to increase mechanical stability (e.g., gelatin methacrylate, cellulose, alginate). It can be rehydrated in a range of buffers and cell culture media to support multiple cell types and specific bioinks.

Bioinks that can be printed include collagen, alginate, fibrin, decellularized extracellular matrix, methacrylated gelatin, methacrylated hyaluronic acid, and more. Check out the Allevi shop for options.

Storage and Handling

The product ships and is stored at room temperature. We recommend storing the dry LifeSupport® at 4°C for prolonged periods to ensure maximum shelf life. Limit exposure to air, as the dry LifeSupport® is highly hygroscopic.

Rehydrated LifeSupport® is highly temperature-sensitive, and will begin melting above 32°C. We recommend that preparation, handling, and printing be performed in a temperature-controlled room at 23 ̊C or less. Rehydrated LifeSupport® can be stored in the noncompacted state (i.e., prior to centrifugation) for 7 days under refrigeration to avoid degradation.

Once compacted, LifeSupport® should be used within 12 hours and the temperature should not exceed 32°C during handling or while printing.

Materials

- LifeSupport®

- Centrifuge

- Medium for powder reconstitution

- Dish of choice

- 30G 1″ or 0.5″ needle

- Allevi plastic syringe

Methods

To check the appropriate medium for each material, refer to Table 1, below:

| Bioink | Suspension Media |

| Lifeink® 200 | Cell Culture Media or 1X PBS |

| Lifeink® 240 | Cell Culture Media with 50 mM HEPES |

| Alginate | 0.1 wt% CaCl2 |

| Fibrinogen | Cell Culture Media with Thrombin |

| Matrigel | Cell Culture Media or 1X PBS |

Table 1. Suspension media and centrifugation speed per bioink.

Preparing LifeSupport®:

- Add 40 mL of cold suspension media (refer to Table 1) to the 2 g unit of LifeSupport®

- Vortex this solution for 1 min, ensuring that all of the powder is fully resuspended and not stuck to the tube walls/tip

- Let it stand for 15 minutes at 4 °C to allow LifeSupport® to fully rehydrate

- Centrifuge the rehydrated LifeSupport® at 2000 X g*; for 5 minutes

- Gently pour off supernatant

- If the slurry easily flows after pouring off the supernatant, repeat steps 4 and 5

- Place compacted LifeSupport® in a 6-well plate well or any other dish of choice

- It should be difficult to pour the slurry into the dish, so you may need to use a spatula

- During handling, do not allow room temperature to exceed 23 °C

Settings to print with Lifeink® 200 (diluted to 23 mg/mL):

| Speed (mm/s) | Layer height (mm) | Nozzle Diam (mm) | Gauge |

| 12 | 0.2 | 0.2 | 30 |

| Pressure (psi) | Crosslink (sec) | Print Temp (°C) |

| 30-40 | 0 | 4˚C |

If you have any problems while printing using FRESH technique, check our FRESH troubleshooting guide.

References

Lee A, Hudson AR, Shiwarski DJ, Tashman JW, Hinton TJ, Yerneni S, et al. 3D bioprinting of collagen to rebuild components of the human heart. Science. 2019;365(6452):482-7.