Allevi Blog

Allevi Author: Allevi and Dr. Anthony Atala

- Updated on April 9, 2020

With a 12% success rate for drugs entering clinical trials, there is no doubt that drug companies need more accurate prediction platforms to help them save billions in bringing a drug to market. 3D cellular models, such as spheroids, organoids and organ-on-chips, offer a promising solution to this issue. But how can these models be built at the complexity and scale needed for pharma? Bioprinting’s ability for increased complexity and automation is the clear answer. Read our co-authored paper with Dr. Anthony Atala, Director of the Wake Forest Institute for Regenerative Medicine (WFIRM) and featured on TED, describing the potential of bioprinting to improve drug testing.

“Bioprinted organoids can potentially provide significant benefits to drug companies and patients alike,” said Atala. “More accurate and faster testing brings new drugs to market sooner, and the possibility of engineering tumors in the lab from a patient’s own cells mean patients can get the best therapy right away – without time spent taking therapies that won’t work for them.”

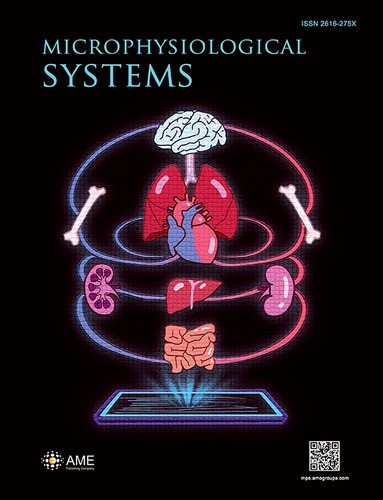

Microphysiological systems (MPS) offer great potential for improving pre-clinical testing for pharmaceutical treatments and novel therapies. These advanced in vitro models are designed to recapitulate the basic functions of living tissues or organs through dynamic culture and biomimetic microarchitecture. Increasing advancements in MPS design require advanced fabrication methods, such as extrusion bioprinting. Extrusion bioprinting presents the ability to automate fabrication of these systems in a simplified, one-step process, while providing the ability to fabricate complex, reproducible designs that incorporate dynamic culture, 3D microtissues and integrated sensors for analysis into a single system. This work reviews the main components that constitute these systems, current state-of-the-art MPS fabricated via extrusion bioprinting, and future considerations for the development of MPS.