Overview

PCL (polycaprolactone) is a thermoplastic polymer that offers enhanced control over mechanical properties of final 3D structures. It is specifically developed and optimized for bioprinting of 3D structures. PCL may be used on its own or printed with matrix bioinks such as gelatin methacrylate. There are multiple ways of bioprinting PCL; the thermal method, wherein you raise the temperature to melt the thermoplastic pellets, and the solubilized method, wherein you use a solvent to dissolve the pellets. Follow this protocol for bioprinting hard tissues using solubilized PCL.

The recommended preparation provided in the instructions below yields a streamlined printable biomaterial that creates reproducible 3D printed constructs. However, preparation can be modified by users to suit their needs. Solubilized PCL allows you to print at room temperature while fine-tuning the viscosity of the PCL for great printability.

Materials

- PCL

- Dichloromethane (DCM)

- Plastic Syringe (5mL or 10mL)

- Syringe cap

- Nozzle

- Print surface (petri dish, glass slide, etc)

Methods for Bioprinting Solubilized PCL

Preparing Solvent PCL

- Weigh the desired amount of PCL and add it to a plastic syringe with cap securely attached.

- Add the appropriate volume of dichloromethane (DCM) such that the final concentration of PCL is 1.2g/mL.

- Example: for 1.5g of PCL, 1.25mL of DCM would be added.

- CAUTION: when working with organic solvents such as DCM, be sure to follow appropriate SOPs and safety guidelines.

- Place a stopper inside the syringe and cover the back opening of the syringe with parafilm.

- Leave the syringe (cap down) for 4 hours to allow the PCL to dissolve.

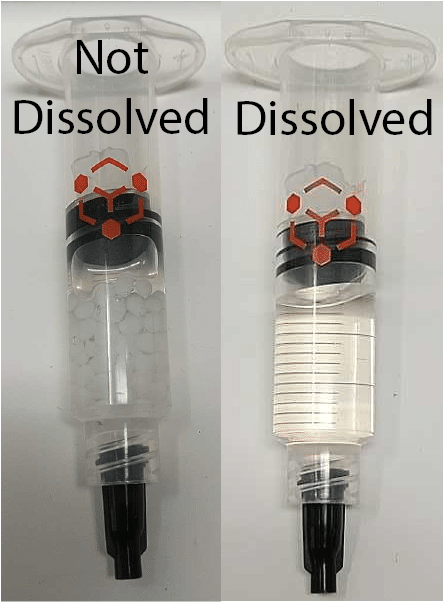

- Once fully solubilized (no observable cloudiness, see figure 2) turn the syringe so the cap is facing up to allow air to rise to the top.

- With the syringe held in this position, unscrew the cap and attach nozzle of choice.

- Note: depending on the nozzle inner diameter and flow profile, different print settings will be required to optimize extrusion. Please refer to the print settings table at the end of this protocol for recommendations.

- CAUTION: when working with organic solvents such as DCM, be sure to follow appropriate SOPs and safety guidelines.

- Continuing to hold the syringe upside down, carefully push the back of the stopper to remove air from the syringe and extrude material to prime the nozzle.

- Load syringe into extruder, calibrate and test extrusion.

- Load desired print file and begin printing.

Print Settings: Solvent Method

| Nozzle Gauge | Nozzle ID (mm) | Layer Height (mm) | Speed (mm/s) | Pressure (PSI) | Print Temp (℃) |

| 27G Tapered Plastic | 0.203 | 0.15 | 6 | 100-120 | 20-25 |

| 25G Tapered Plastic | 0.28 | 0.2 | 6 | 80-100 | 20-25 |

| 30G Metal | 0.233 | 0.15 | 2 | 120 | 20-25 |

| 27G Metal | 0.335 | 0.1-0.2 | 4-6 | 90-120 | 20-25 |

| 25G Metal | 0.437 | 0.3 | 4 | 120 | 20-25 |

| 23G Metal | 0.564 | 0.5 | 6 | 110 | 20-25 |

Troubleshooting

- If there is stringing observed during print, try lowering the print speed, using a nozzle with smaller I.D., or increasing the extruder temperature.

- If the printed structure is taller than it is wide, it is more likely that it will detach from the print surface. To prevent this, use a textured print surface such as the sandpaper printing surface.

We hope you found this protocol helpful for bioprinting hard tissues using PCL! Click here for more bioprinting protocols.