- About Allevi

- Bioprinters

- BioinksAdditivesAdditivesBioinksAdditivesAdditivesAdditivesAdditivesAdditivesAdditives

- Software

- Services

- Resources

- Support

Menu

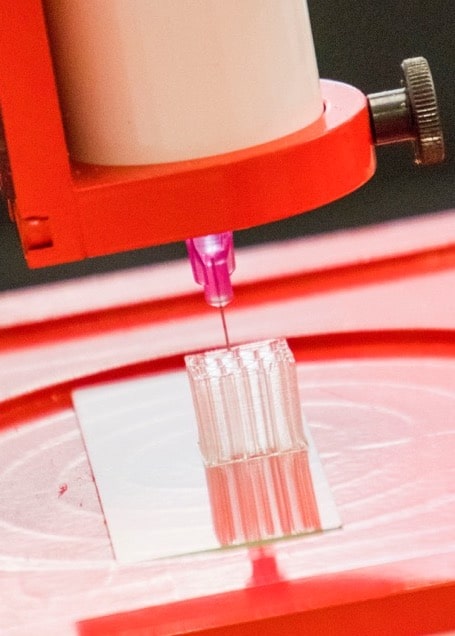

Every bioink requires specific conditions and printing parameters for an optimal extrusion. Despite differences between materials, problems with correct deposition often stem from the same reasons. Follow our general hydrogel extrusion troubleshooting guide to deal with the most common issues regarding biomaterial extrusion.

If you still have problems printing your material contact our Allevi Support Team at [email protected].