Sodium alginate is a naturally derived biomaterial that can be chemically crosslinked with calcium chloride to create cell-laden hydrogels. These reagents are used in a variety of applications including bioprinting. The recommended preparation provided in the user instruction below yields a streamlined matrix bioink that supports 3D printed cell-laden constructs. As sodium alginate cannot support itself before it is crosslinked, we recommend using Pluronic F127 or a gelatin bath as a sacrificial support. However, users can modify the preparation to suit their needs. Read on to learn the methods of sodium alginate bioprinting.

Storage and Handling

- Dry Sodium Alginate powder should be stored at room temperature.

- Solubilized Sodium Alginate should be stored at 4ºC in an airtight container.

- Calcium Chloride should be stored at room temperature in a dry environment.

You Will Need

- Sodium alginate

- Calcium chloride

- LifeSupport for FRESH

- Needles

- We suggest these 0.25″ 30 gauge needles for 2% alginate solutions

- We suggest these tapered 25 gauge needles for 5% alginate solutions

- Petri dish or well plate for printing

- Optional: transwell plates can help avoid sample loss or damage throughout experiment. Keep in mind though that transwell membranes may inhibit imaging processes.

- Sterile filters

- Syringes

- For the Allevi 1/3/6: 5mL syringes

- For the Allevi 2: Sterile 10 mL syringes

- Media without calcium or magnesium

- Sodium alginate can be dissolved in deionized water.

- Deioinized Water

- Sterilized Phosphate Buffered Saline (PBS)

Instructions for Use

Prepare the Sodium Alginate

- Dissolve 2% or 5% (w/v) sodium alginate in media without calcium or magnesium under stirring at 60°C. Regularly check and mix with spatula to speed up process. (Sodium alginate may be dissolved up to 24-48 hours in advance of use.)

- *Sterile filter sodium alginate with a 0.45 µm filter into a sterile container.

- Allow solution to reach 37°C. Mix in desired cell type and concentration. Be sure to pipette vigorously to achieve a homogenous solution.

Prepare Calcium Chloride solution

- Dissolve 100 mM (0.011 g/ml) concentration of calcium chloride in deionized water. (Calcium chloride solution may be made 24-48 hours in advance of use.)

- You will need enough calcium chloride to be able to submerge your samples.

- *Sterile filter calcium chloride solution with a 0.22 µm filter into a sterile container.

Prepare FRESH

For use with alginate, you will suspend FRESH in 0.1 wt% CaCl₂ solution as noted in our protocol on how to prepare FRESH.

Print Settings

| Layer Height (mm) | Speed (mm/s) | Pressure (PSI) | Temperature (°C) | Needle | Crosslinking | |

|---|---|---|---|---|---|---|

| Alginate (2%) | 0.15 | 6 | 7.5 | RT | 0.25″ straight 30G | Chemical (CaCl2) |

| Alginate (5%) | 0.15 | 6 | 15 | RT | 0.25″ straight 30G | Chemical (CaCl2) |

Post-print settings

- While printing, heat the sterilized solution of CaCl2 to 40-50°C.

- After the printing has finished, crosslink the finished structures in the heated solution. Crosslink for 15 minutes at room temperature. This will melt the FRESH while chemically crosslinking the alginate.

- After crosslinking samples, wash each structure 3 times with PBS, then add media.

- Incubate as needed.

* If not using cells, sterile filtering steps may be skipped.

Notes

- Adjust gelation time and gel stiffness by varying the concentration of alginate and calcium chloride as well as the crosslinking time. For help adjusting print parameters please contact [email protected].

- A fill volume change of more than 2 mL may affect pressure settings.

Further Information

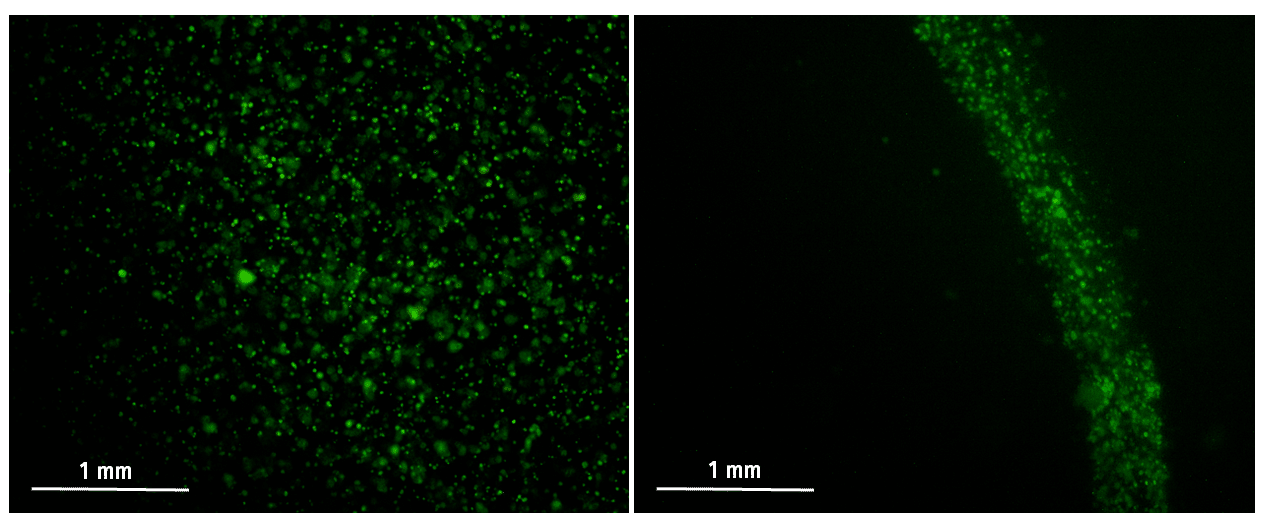

- Bioprinted alginate viability results

- Sodium Alginate SDS

- Calcium Chloride SDS

- Sodium alginate troubleshooting guide

- FRESH troubleshooting guide

For further questions about sodium alginate bioprinting or information about these products, please contact [email protected].