Introduction

Sodium alginate is a polymer present in brown algae (Phaeophyceae) cellular walls which is the main commercial source of this biomaterial. In general, alginates consist of L-guluronate (G) and D-mannuronate (M) residues creating blocks of only G, only M, or a combination of both [1]. The particular composition of blocks in sodium alginate hydrogel will dictate its mechanical properties that improve with longer G-blocks and higher overall molecular weight.

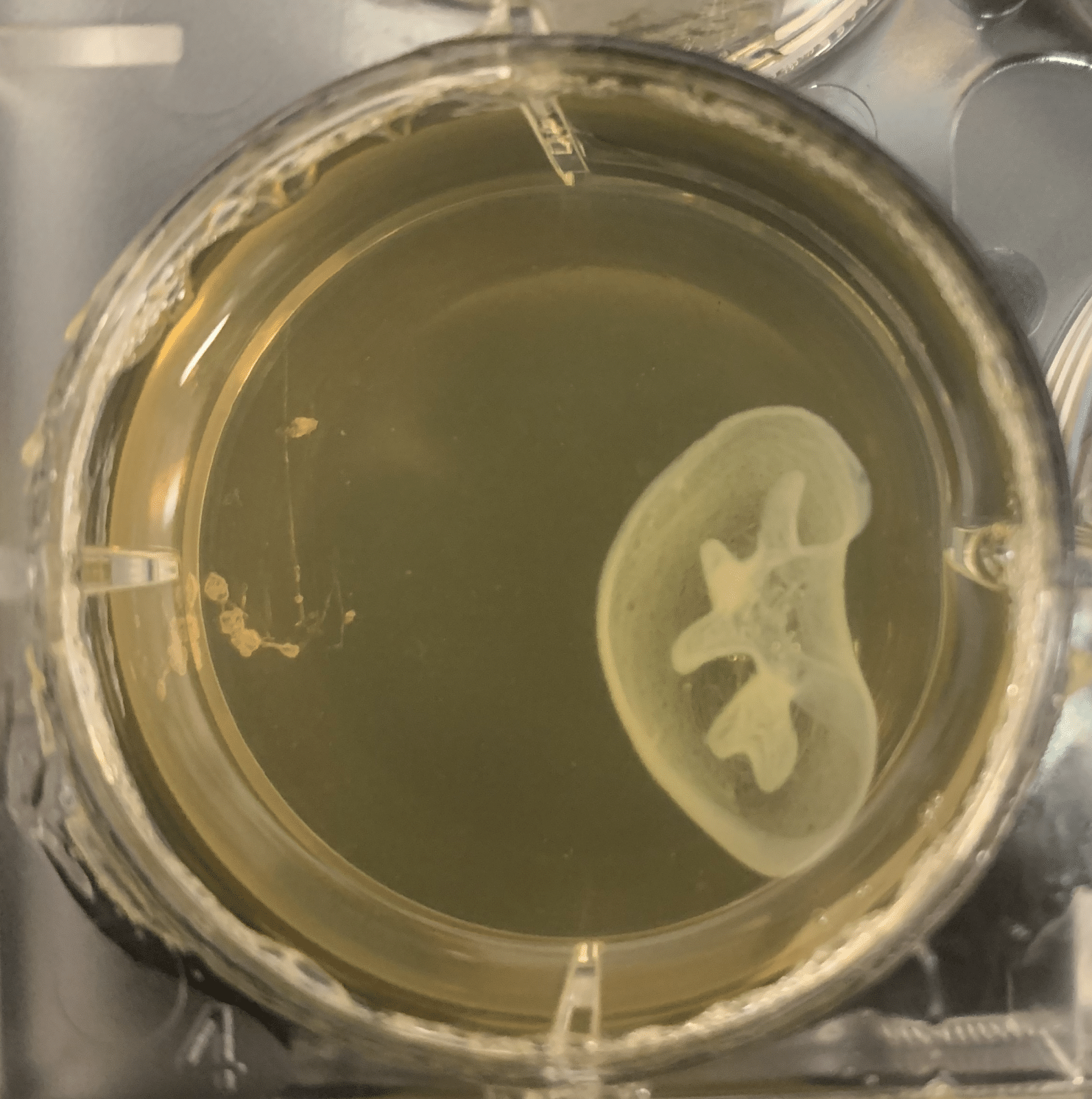

Sodium alginate can be crosslinked using divalent cations such as Ca2+ or Br2+. During the crosslinking, these ions are coordinated by G-blocks forming a hydrogel network. Because of the ease of use and cytocompatibility, sodium alginate hydrogels are usually created by ionic crosslinking using calcium chloride (CaCl2) [2]. Nevertheless, covalent, thermal and cell-based crosslinking mechanisms are also available.

Due to low cost, good biocompatibility, and low toxicity, sodium alginate has a long record of various applications from drug delivery, through wound healing, to tissue engineering. Many different cell types showed their cytocompatibility with sodium alginate, including myoblasts, hepatocytes, and MSCs to name a few [3, 4]. Even though it shows a broad range of cell support, sodium alginate doesn’t provide cell attachment sites. It is usually physically encapsulating cells creating 3D environment. It is, however, possible to chemically modify its structure to include cell-binding motifs or introduce additives providing this functionality.

Sodium alginate is also a popular and widely used bioink. However, in low concentrations, it can present low viscosity creating challenges for accurate 3D deposition. Thus, It is often mixed with other materials such as chitosan or GelMA. Direct printing of sodium alginate is also possible with application of methods such as coaxial bioprinting or FRESH technique.

Materials and methods

You can buy sodium alginate powder in our webshop.

For general recommendations for working with SA, start with our protocol on bioprinting sodium alginate.

Troubleshooting

I need to know the specific type of SA that you offer.

Our sodium alginate is derived from Lessonia nigrescens and Lessonia trabeculata algea without any further additives or chemical modifications. Mannuronic to guluronic acid ratio (M/G) is 0.5.

SA doesn’t dissolve easily during the preparation.

Dissolving SA can take several hours. To speed up the process dissolve SA at 60°C using a magnetic stirrer. Breaking bigger clumps of SA manually using a spatula can help as well.

Important note: If you are dissolving SA in cell culture media containing heat-sensitive additives, lower the temperature to around 37°C for SA dissolution. However, it might take longer. If your media contains FBS, long stirring can create bubbles and foam formation. If possible, skip FBS in media used for SA dissolution.

I would like to prepare more SA and keep it for later use.

SA can be prepared 24-48 hours before printing and stored at 4°C.

I need sterile SA to print with cells.

To prepare sterile SA for bioprinting we recommend filtering SA using filters with 0.45 um pore size. Make sure that your crosslinker solution is also sterile. You can filter it using filters with 0.2 um pore size.

SA constructs dissolve easily during cell culture or during post-processing.

This could happen due to crosslinking issues. First of all, make sure that your initial crosslinking time is sufficient. You can extend it and test what time gives the best crosslinking results without compromising cell viability.

It is also possible that Ca+2 ions are released from the scaffold and the crosslinked structure is getting weaker over time. If you use PBS for washing at any step of cell culture or post-processing, the Ca+2 ions might precipitate with phosphate from the buffer. In this case, you can replace PBS with HEPES, for example.

If you would like to extend construct stability in cell culture or in the in vivo scenario, you can consider using an alternative crosslinker. For example, SA scaffolds crosslinked using BaCl2 display better mechanical properties comparing to CaCl2. However, it might have a negative impact on cell viability.

Cells display poor viability in SA.

Poor cell viability in SA hydrogels might be dependent on many different variables. You can learn more about cell viability in 3D cultures in our dedicated guide.

Cells have limited proliferation and/or migration in SA.

This might occur due to the lack of cell-binding sites in SA. You can improve this by chemical modification of SA hydrogels and covalent binding of cell-binding peptides or applying protein additives.

SA is too liquid and it spreads on the building surface before crosslinking.

SA in low concentrations has low viscosity and it doesn’t support its shape after printing, making it necessary to use additional support. We recommend using Pluronic as support material or LifeSupport for the FRESH bioprinting technique that will provide physical support and crosslinking of your hydrogel at the same time. You can also use the coaxial bioprinting method to extrude SA and crosslink it with your solution at the same time.

The needle clogs when printing SA using the FRESH method.

It is possible that CaCl2 included in the support bath started crosslinking SA in the printing needle. To avoid clogging, keep the needle clean of residual slurry by wiping it with a sterile paper tissue. To remove the clog try immersing the tip of the needle in PBS for 30 seconds and try test extrusion using the extrude button in the software under the Extruder section. If it doesn’t help, increase the pressure, and try extruding again. If the clog remains, replace the needle with a fresh one.

SA printed with the FRESH method has poor resolution and/or the printed lines are not smooth.

To improve bioprinting quality of SA using the FRESH method, we recommend using LifeSupport, an optimized gelatin microparticle-based support material. You can also see more tips in our FRESH troubleshooting guide.

If you have any more questions about sodium alginate bioprinting, you can contact the Allevi Success Team at [email protected].

References

[1] K.Y. Lee, D.J. Mooney, Alginate: Properties and biomedical applications, Prog. Polym. Sci. 37 (2012).

[2] G.T. Grant, E.R. Morris, D.A. Rees, P.J.C. Smith, D. Thom, Biological interactions between polysaccharides and divalent cations: The egg-box model, FEBS Lett. (1973).

[3] F. Lim, A.M. Sun, Microencapsulated islets as bioartificial endocrine pancreas, Science (80-. ). 210 (1980) 908–910.

[4] X. Huang, X. Zhang, X. Wang, C. Wang, B. Tang, Microenvironment of alginatebased microcapsules for cell culture and tissue engineering, J. Biosci. Bioeng. 114 (2012)