- About Allevi

- Bioprinters

- BioinksAdditivesAdditivesBioinksAdditivesAdditivesAdditivesAdditivesAdditivesAdditives

- Software

- Services

- Resources

- Support

Menu

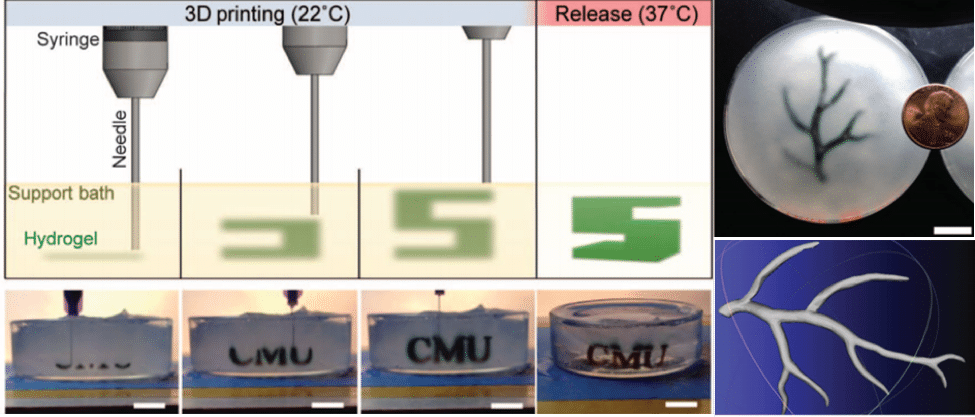

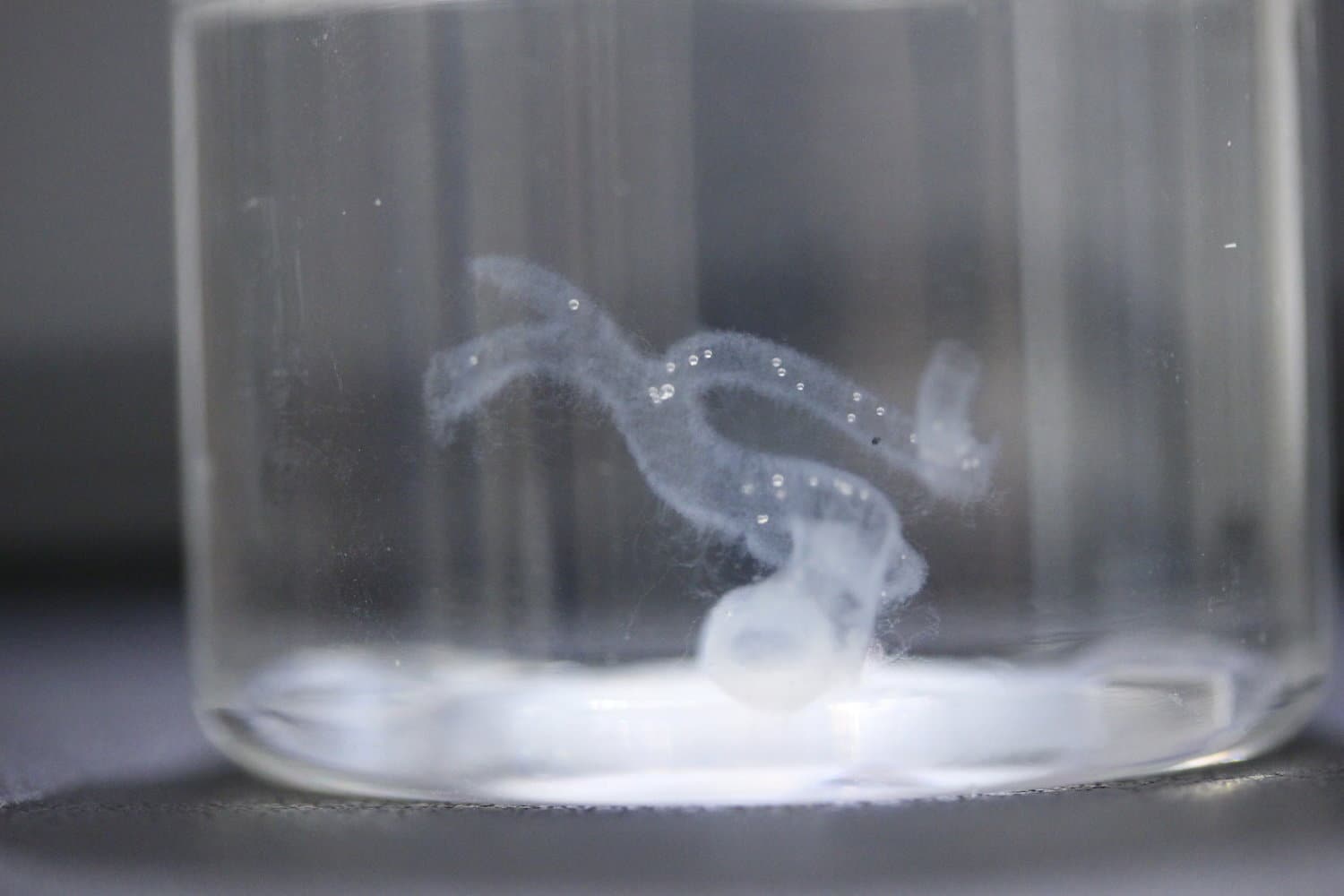

Freeform reversible embedding of suspended hydrogels, also known as the FRESH method, allows for the bioprinting of soft cell encapsulated materials such as collagen or alginate (1).

If you’re unfamiliar with 3D bioprinting in general, our ‘What is 3D bioprinting‘ article offers a brief introduction. For a more in-depth overview of the bioprinting process, our Bioprinting 101 guide is also recommended.

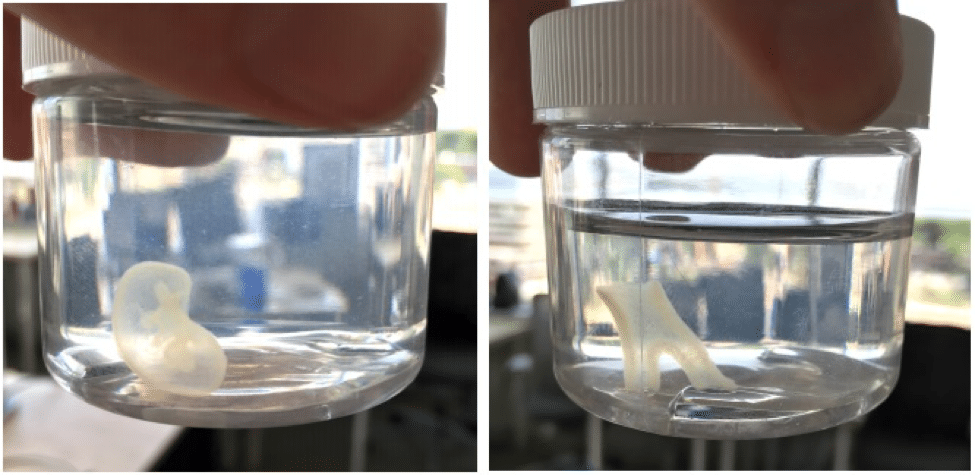

The FRESH method utilizes a support hydrogel as a temporary, thermoreversible support that can be washed away after printing. The FRESH support reagent is comprised of processed gelatin microparticles with a Bingham plastic rheology. This biocompatible material offers temporary support of fragile materials used for bioprinting.

Using the gelatin-slurry as support material, biomaterials such as collagen and alginate can be printed in complex geometries that would otherwise be impossible to fabricate. This method is compatible with your Allevi 1, Allevi 2, or Allevi 3 bioprinter and was specifically developed and optimized for use on the Allevi platform. FRESH has been adopted by leading researchers working in soft tissues.

Standard FRESH method can be also improved by applying LiFeSupport material – standardized and ready to use gelatin microparticles. Using this form of printing support resulted in much higher resolution of prints and smoother geometry of extruded lines [2].

You can buy LifeSupport for the best FRESH bioprinting results in our webshop.

Protocols:

This guide refers to the original FRESH bioprinting method (FRESH 1.0). For FRESH printing with LifeSupport, please refer to our protocol.

It is possible that the gelatin was overworked during the blending process and too much heat was introduced to the system. It may cause gelatin melting and result in inappropriate particle size. Before discarding the batch, try the following steps:

If you have any more questions regarding the FRESH troubleshooting guide, you can contact the Allevi Customer Success Team at [email protected]. Click here to read more about the team that developed the FRESH method. And for more bioprinting guides, tips and tricks, visit the Allevi protocols page.

References